Fluidized Bed Freezers – Efficient and Gentle Solution

Rapid and individual freezing for berries, seafood, ready meals and other products

Contact usHow Does a Fluidized Bed Freezer Work?

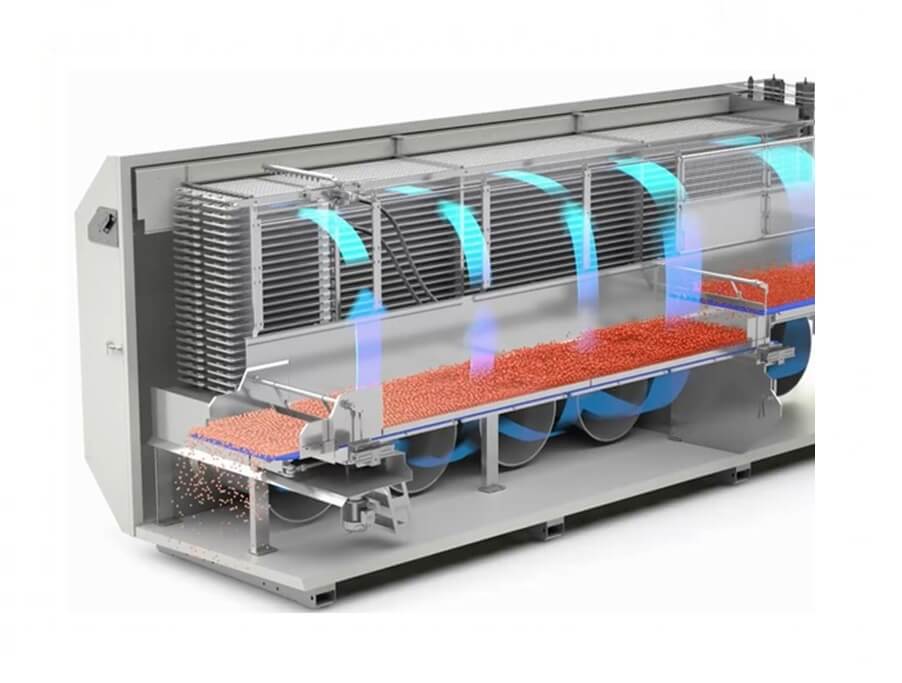

A fluidized bed freezer uses a powerful stream of extremely cold air that is blown through a perforated conveyor belt. Products are placed on the belt, and the air lifts lighter items partially into the air — they appear to “float” in the airflow. This allows cold air to surround the product from all sides, enabling rapid and even freezing.

This method prevents products from sticking together and reduces clumping, which is especially important when processing delicate foods like berries, vegetable cubes, seafood, and other small items. The fluidized freezing process helps preserve the structure, flavor, appearance, and nutritional value of the products.

The result is individually frozen, high-quality products that are easy to handle, transport, and package. Fluidized bed freezers are particularly well suited for food industry production lines that require high throughput, hygiene, and energy efficiency.

Benefits

Fast Freezing

Thanks to high airflow, products freeze quickly and evenly, preserving texture and taste.

Individually Frozen Products

Products freeze separately without clumping – making packaging and further handling easier.

Gentle Handling

The airflow does not damage the products, maintaining their natural structure.

Energy Efficiency

Optimized airflow and structure ensure low energy consumption and operating costs.

Easy to Clean

The design prioritizes food safety – cleaning is fast and effective.

Applications

Fluidized bed freezing is especially suitable for products that need to be frozen quickly and kept separate. The method works excellently across various industries.

Berries, fruits, and vegetables – fast freezing preserves structure and nutrients.

Shrimp, fish fillets, and other seafood – individually frozen products are easier to handle.

Poultry pieces and meats – maintain shape without freeze damage.

Ready meals and industrial portions – continuous freezing for production processes.

Plant-based products – efficient freezing without sticking together.

Different Models of Fluidized Freezers

| Model | Capacity | Length |

|---|---|---|

| 2/1 | 1,350 kg / hour | 2,700 mm |

| 3/2 | 2,000 kg / hour | 3,805 mm |

| 4/2 | 2,600 kg / hour | 4,880 mm |

| 5/2 | 3,950 kg / hour | 5,950 mm |

| 6/2 | 4,000 kg / hour | 7,025 mm |

| 7/2 | 4,650 kg / hour | 8,095 mm |

| 8/2 | 5,300 kg / hour | 9,170 mm |

| 9/2 | 5,900 kg / hour | 10,240 mm |

| 10/2 | 6,600 kg / hour | 11,340 mm |

| 11/2 | 7,300 kg / hour | 12,378 mm |

| 12/2 | 8,000 kg / hour | 13,450 mm |

| 13/2 | 8,600 kg / hour | 14,522 mm |

| 14/2 | 9,300 kg / hour | 15,594 mm |

| G12 | 13,000 kg / hour | 15,600 mm |

| G13 | 14,000 kg / hour | 16,800 mm |

| G14 | 15,000 kg / hour | 18,000 mm |

Tailored Solutions

We provide fluidized bed freezing solutions for various production capacities and product types – from small production lines to large industrial plants. We’re happy to help you choose the equipment that best fits your process, regardless of the manufacturer.

Contact us or request a quote